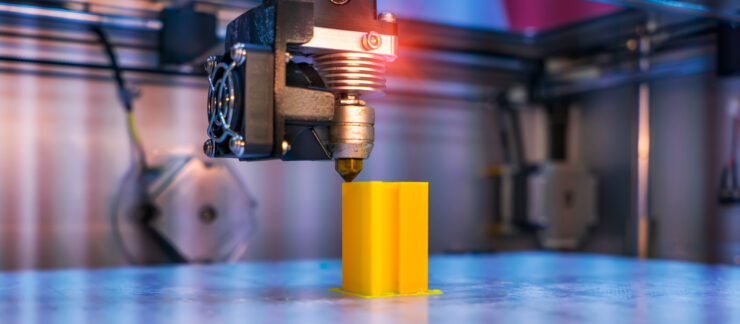

As CEO and founder of closely-held WhiteClouds, which operates the largest 3D color printing facility in the world, Jerry Ropelato is passionate about using the technology to create stunning models for the architecture, entertainment, retail and medical sectors. He points out that 3D printing is helping to further personalize healthcare and can play a pivotal role in helping doctors not only better tailor their care to each patient’s needs, but also in the way they devise diagnoses and treatment plans. In this interview with BioTuesdays.com, Mr. Ropelato discusses how his company is working with the health care sector.

Let’s start with a brief history of WhiteClouds.

We’re a three-year-old, self-funded company with 55 employees and more than 50 production printers. Our expert team creates full color, life-scale anatomical models derived from an individual’s medical image or custom designs. Our models provide pre-operative planning, patient education and consultation, and innovative custom solutions for health care providers, educators, institutions, manufacturing and the public. And we received a fair bit of publicity this year when we 3D printed an arm brace for Carolina Panthers’ linebacker, Thomas Davis, who played in Super Bowl 50 with a broken arm, the first-ever piece of 3D printed equipment used during an NFL game.

According to Mr. Ropelato, WhiteClouds can now use 3D printing to replicate anything inside the body, including personalized medical models ranging from hard and soft tissue, organs, and even cancerous tissue

How did you become interested in medical 3D printing?

I experienced the scare of my life 14 months ago, when my doctor noticed something during my annual physical and sent me for a CAT scan because he suspected lymphoma. To make a long story short, it was only a small lump in my throat. But the process of getting an explanation through a CAT scan and the surgical procedure did nothing to calm my nerves. I came away from the experience knowing we had the ability to figure out a better way. So a team at WhiteClouds figured out a great way to 3D print personalized medical models, ranging from hard and soft tissue, organs, and even cancerous tissue. We can now replicate anything inside the body. We started working with some local hospitals in Utah six months ago and now have expanded our R&D efforts into six different states. We’re early days but getting a great response.

Can you provide some examples of how you’re working with the health care sector?

Let me begin by saying that doing a 3D print from a CAT scan or MRI is not easy. Beginning with what we call a segmentation issue, we take a CAT scan that is built in layers and select the anatomy to print. There is a lot of interpretation, using sophisticated software, to take a black and white, 2D image and turn it into a full-color, 3D product. There are also a lot of steps involved to get a file into a printable state. Then, we have to determine the material to use to print. We have 180 different materials and use six different technologies, which adds another layer of complexity. Of course, we help physicians and hospitals figure out what they’re trying to accomplish with a model. For example, they could be sharing the model with a patient for educational purposes, or it could be pre-planning or clinical practice before surgery, such as all the steps required in repairing a rib cage.

According to Mr. Ropelato, WhiteClouds can now use 3D printing to replicate anything inside the body, including personalized medical models ranging from hard and soft tissue, organs, and even cancerous tissue.

What’s the market opportunity in imaging?

There are 233 million CAT scans, MRIs and ultrasounds performed in the U.S. each year, so we’re excited about the market opportunity. WhiteClouds can provide these models faster than any company because of our capacity. We have provided pre-operative planning models in as little as 14 hours after receiving the CT scan or MR image.

Turning a black and white, 2D image into a full-color 3D product requires a lot of interpretation and sophisticated software. WhiteClouds has 180 different materials and uses six different technologies

How do patients typically respond to these new 3D printed models?

We’ve heard from a great many doctors that these models instill a lot of confidence in patients before a procedure. It’s one thing to have a standard model and have a doctor point to a specific area; it’s another thing to be able to see, for example, exactly where the cancer is in your body and how large it is. A heart surgeon at Phoenix Children’s Hospital has told us that parents often have a difficult time deciding whether they should put their infant through the trauma of heart surgery. But once he shows them an actual 3D printed model of their child’s heart, they almost always go ahead and approve the surgery. And you can only do that with a model of a personalized heart or organ in the body. In many ways, these models are empowering patients and their families.

Can 3D printers print any part of the human anatomy?

Turning a black and white, 2D image into a full-color 3D product requires a lot of interpretation and sophisticated software. WhiteClouds has 180 different materials and uses six different technologies.

Yes and no. There’s been a great deal of progress in the first stage of this process, building a scaffold to lay down stem cells to create a body part, like an ear, for example. The process is called 3D bioprinting. One of the leaders in the space is Organovo Holdings (NYSE MKT:ONVO), which recently presented data supporting 3D bioprinting of liver tissue for drug toxicity testing and liver fibrosis modeling. In addition, the University of Louisville claims it will 3D print a fully functioning heart for transplantation in 10 years. While that timeline is possible, the FDA approval process could greatly extend its arrival on the market.

What was the significance of your acquisition of 3DplusMe?

3DplusMe has worked with leading brand partners, including Marvel, Hasbro, Major League Baseball, Major League Soccer, Assassin’s Creed, DreamWorks, and Halo. It also has channel partnerships with Target, Toys ‘R’ Us, Walmart and Sam’s Club. But what really attracted us to 3DplusMe was their software platform, which allowed us to build out our platform much faster than we could have done alone. With the acquisition of 3DplusMe, we’ve introduced a 3D-as-a-Service (3DaaS) platform, which enables brands and channels to create 3D experiences and turn them into full-color 3D printed products. The 3DaaS platform provides a turnkey, scalable system to bring personalized and customized full-color 3D printed products to the mass market.